Astro Tracker Build - Prototype and Rotation Speed Testing

January 23, 2019

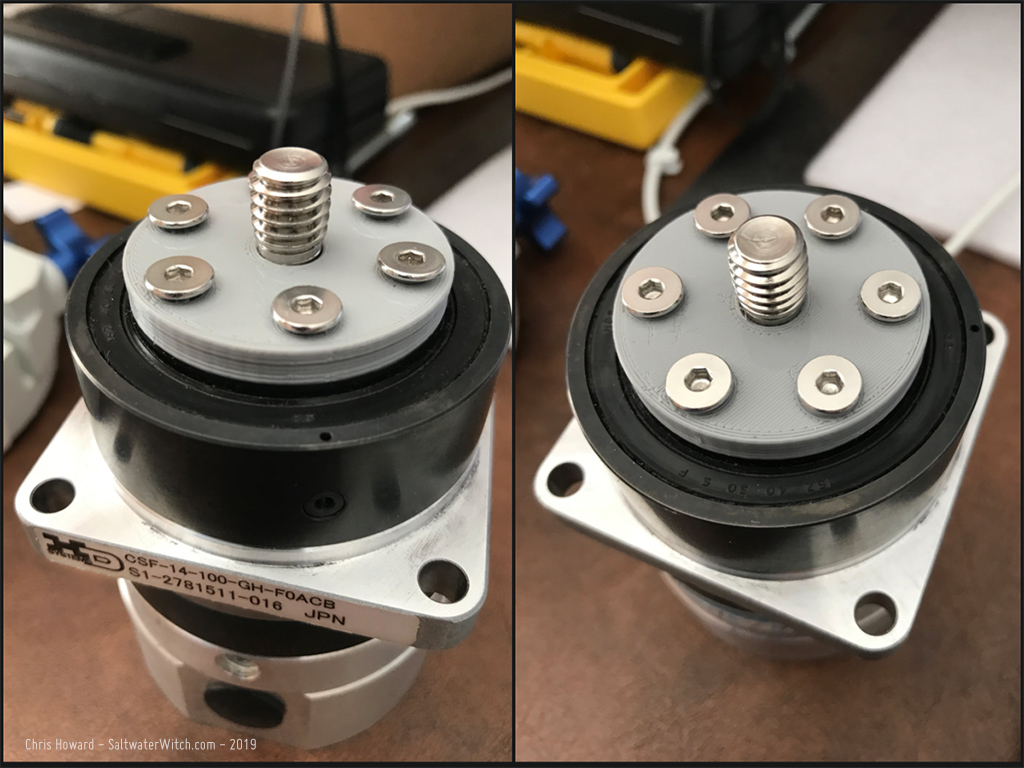

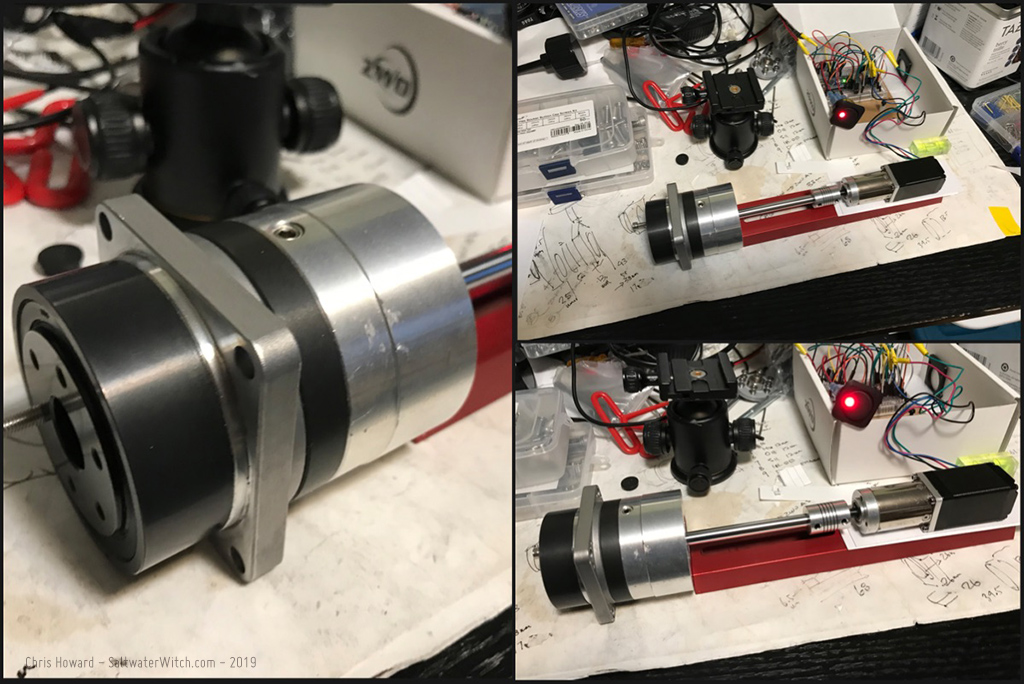

Our beautiful planet rotates on its axis once every 23.93447 hours (23 hours, 56 minutes, 4.091 seconds). This is one sidereal day--sidereal time is based on the earth's rate of rotation measured relative to the stars that are--for the most part--fixed in position. Here we go: 23.93447 hours = 86164.091 seconds. So, we need to do a 360 degree rotation of the right ascension motor shaft in 86164.091 seconds to match the earth's rotation speed. Sounds simple enough. Backing into the time/revolution (360 deg) before the 100:1 gearhead ratio, we have: 86164.091 / 100 = 861.64091 seconds, or 14.3606 minutes / 360 degrees, which is close to what I'm getting for a full rotation with my current test system: NEMA 11 stepper + 100:1 planetary gearhead and A4988 stepper driver running with 1/16 microstepping. I'm probably going to build the second prototype with a NEMA 17 + 139:1 planetary gearhead, but still waiting on that to arrive. And I will most likely continue to run with 1/16 microsteps. The downside is microstepping significantly reduces torque--I'm sacrificing torque for slower, smoother steps, but I'm thinking I will make up some of this with the 100:1 harmonic drive gearhead (CSF-14-100-GH-F0ACB). The idea is to get the motor with the planetary gearbox to do one rotation in a little over 14 minutes, and then by adding the harmonic drive I'll multiply the rotation time by 100, and we should end up around 86164.091 seconds, or one sidereal day. I think that sounds right? (Also, don't forget the direction is reversed with the harmonic drive--clockwise rotation of the wave generator results in the flexspline moving counterclockwise).

The shot below has my attached 3D printed adapter for a camera mount. Once I test the rotation speed adequately, I will try out some long exposures with the Nikon.

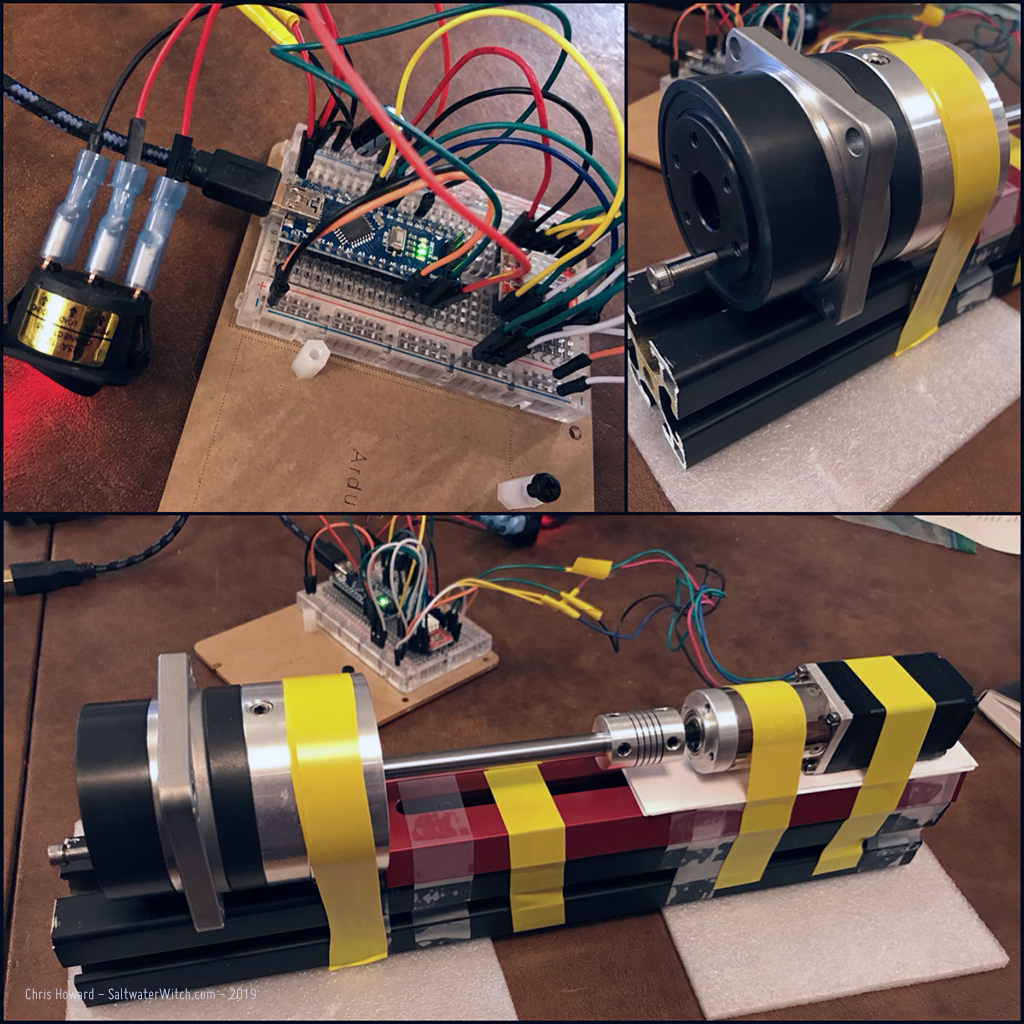

Here's the latest component and wiring setup, driven by an Arduino Nano and A4988 Stepper Driver, with the whole thing running off a single 12vdc power supply. The bottom frame is the entire rotation test taped together and functional.