The Underutilized Ferromagnetism Advantage

December 1, 2021

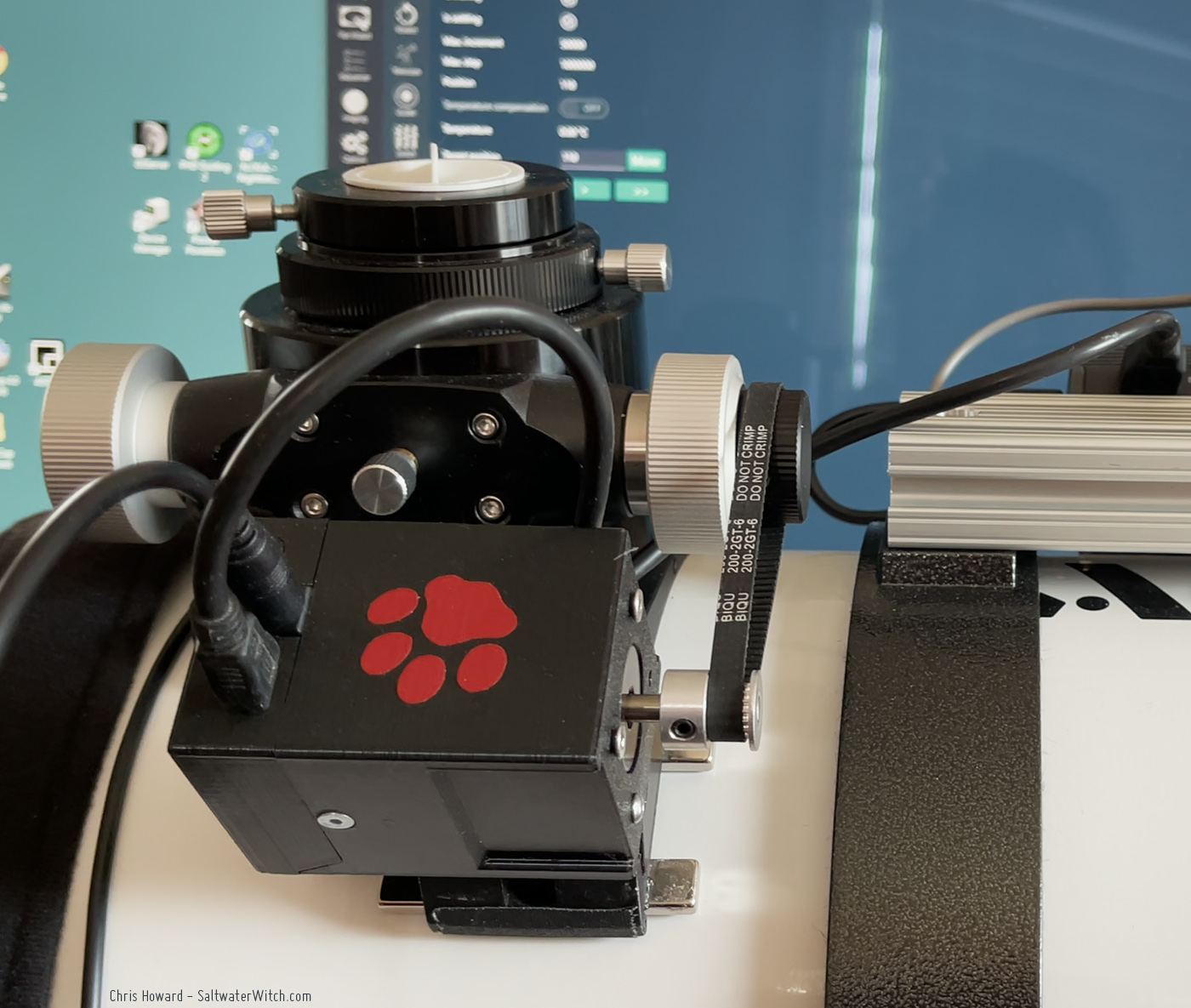

When you see reviews of Newtonian astrographs, you sometimes hear—if the option is available—that you should get the carbon fiber version—for a variety of good reasons, including reduced weight, less susceptible to temperature fluctuations like steel tubes, and that cool carbon fiber look. Steel OTAs (Optical Tube Assemblies) are cheaper, but they also have an underutilized ferromagnetic advantage—meaning magnets love to stick to them. I bought a ZWO EAF (auto focuser) for my Apertura 8" (203mm) newtonian with an 800mm focal length at f/4, but I ended up removing it and using it with the William Optics SpaceCat 51. I have a couple Deep Sky Dad autofocusers, including a new-ish AF3 I had bought for a scope I sold.

I was tinkering with options for using the AF3 for focusing the Newt. The obvious approach would be to use something like the ZWO EAF bracket and couplers. Or... I could take a completely different path, using strong magnets to hold down the focus motor, with a timing belt to turn the 10:1 reduction focus knob.

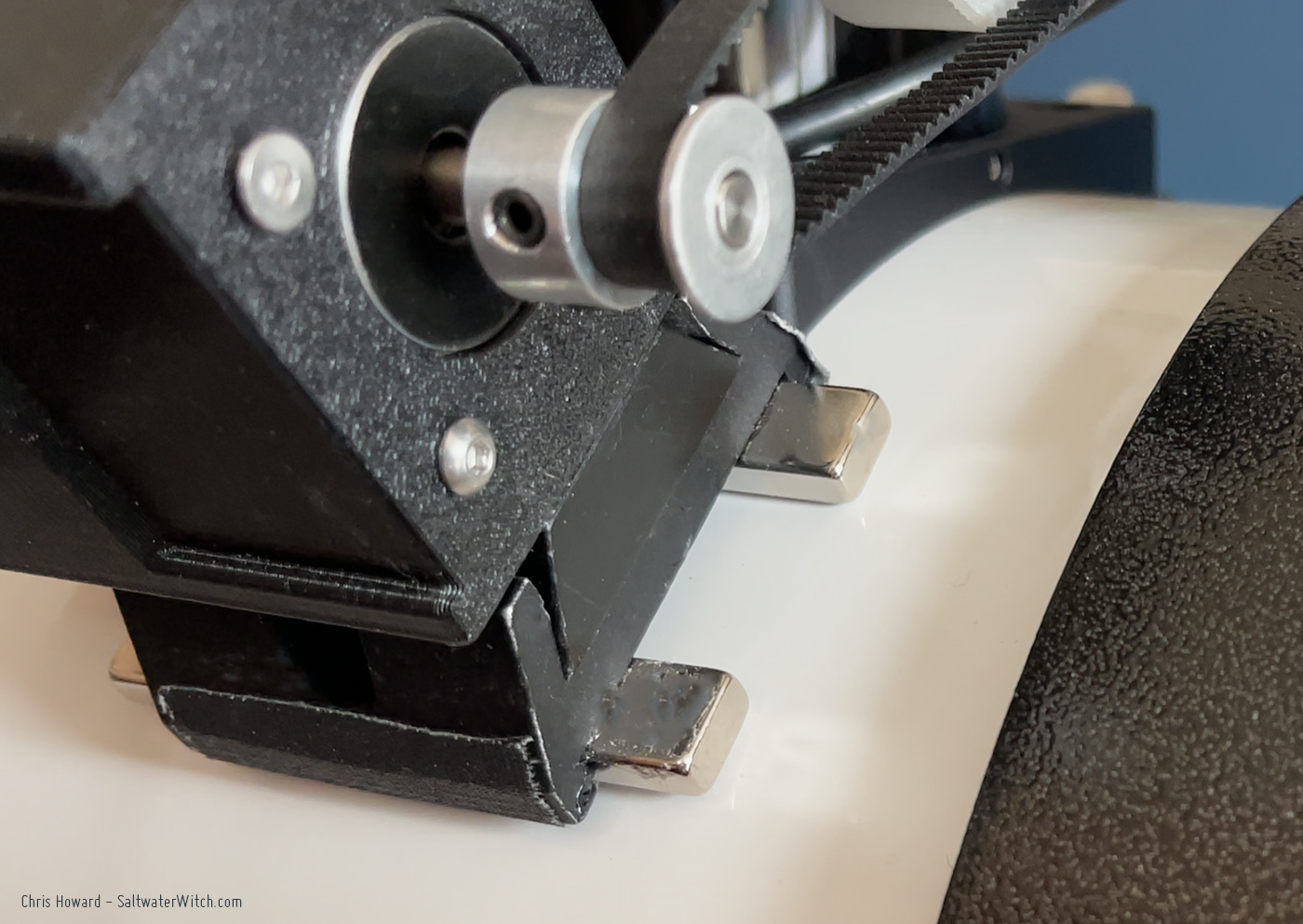

This idea wasn't completely out of the blue. I've been using these neodymium bar magnets for a while to hold down Raspberry Pi devices and my Pegasus Pocket Powerbox. I bought a pack of adhesive-backed metal plates (link below) to hold down these devices. But I don't need them for newtonian scope because the whole thing is steel.

First off, these magnets are crazy strong, and you have to be careful with them. Get them around your tools or a box of hex bolts and it's like angry Magneto tussling with the X-Men. But if you glue two of these to a spare guide cam dovetail bracket, you have the perfect base for your autofocus motor on a steel OTA. I always tape over the magnets with gaffers tape (cloth tape) so I don't scratch my scope. I then glued a small 32mm dovetail to the AF3 motor housing and that's it. I let the E6000 glue dry for 24 hours, and tested out the setup up in N.I.N.A. The belt tension was easy to dial in by carefully sliding the dovetail base and testing the belt. I'm happy to report that everything seems to work well. The motor isn't going to budge with two of these magnets holding it down.

E6000 industrial-strength glue

https://www.amazon.com/dp/product/B071DXL2MP

Neodymium Bar Magnets

https://www.amazon.com/dp/product/B07QWMHGHZ

Adhesive metal plates for magnets

https://www.amazon.com/dp/product/B08CHF846J